কালো পেইন্ট করা ইস্পাত স্ট্র্যাপিংয়ের অতুলনীয় শক্তি এবং দীর্ঘস্থায়িত্ব

চাহিদাপূর্ণ শিল্প পরিবেশে উপাদানের শক্তি এবং কর্মদক্ষতা

কালো রঙের স্টিলের ফিতা কারখানা, গুদামজাতকরণ এবং বাইরের সংরক্ষণ এলাকার মতো কঠোর পরিবেশেও লোডগুলি খুব ভালোভাবে ধরে রাখে। ভেতরের স্টিলটি বড় মেশিনের আঘাত সহ্য করতে পারে, পরিবহনের সময় ধ্রুবক কম্পন মোকাবেলা করতে পারে এবং ১০,০০০ পাউন্ড প্রতি বর্গ ইঞ্চির চেয়ে বেশি চাপ সহ্য করে। প্লাস্টিকের ফিতার সাথে এর তুলনা হয় না কারণ সেগুলি অতিরিক্ত প্রসারিত হয়। এই স্টিল জিনিসটি 0.1% এর কম প্রসারিত হয়, যা ভারী মেশিনের অংশ বা প্যালেটে স্তূপাকার সামগ্রী বাঁধার সময় অনেক বেশি গুরুত্বপূর্ণ। এটিকে আরও ভালো করে তোলে বেকিংয়ের মাধ্যমে প্রয়োগ করা বিশেষ রংয়ের কাজ যা নিয়মিত স্টিলের তুলনায় পৃষ্ঠকে প্রায় 15% বেশি শক্ত করে তোলে। এর অর্থ হল দীর্ঘ রেল বা জাহাজের যাত্রার সময় মালামাল একে অপরের সাথে ঘষার ফলে কম ক্ষয়-ক্ষতি হয়। এই সমস্ত কারণগুলি একত্রিত করলে ফলাফল হয় যে আধুনিক সরবরাহ চেইনে যেকোনো চ্যালেঞ্জ এলেও সম্পূর্ণ যাত্রাজুড়ে মালামাল নিরাপদে থাকে।

টেনসাইল শক্তির তুলনা: কালো রঙের ইস্পাত বনাম প্লাস্টিক এবং কম্পোজিট বিকল্প

ভারী মালপত্রের ক্ষেত্রে ব্যর্থতার সীমা নির্ধারণে টেনসাইল শক্তি হল প্রধান নির্ণায়ক। উচ্চমানের প্লাস্টিকের বিকল্পগুলির তুলনায় কালো রঙের ইস্পাতের বেল্টিংয়ের ভাঙার শক্তি 2–3 গুণ বেশি:

| উপাদান | গড় টেনসাইল শক্তি | দৈর্ঘ্য বৃদ্ধি হার |

|---|---|---|

| কালো পেইন্ট করা ইস্পাত | 5,000–7,000 PSI | <0.1% |

| কম্পোজিট স্ট্র্যাপিং | 2,000–3,500 PSI | 1.5–3% |

| পলিয়েস্টার স্ট্র্যাপিং | ১,২০০,০০০ পিএসআই | 2–5% |

ইস্পাতের প্রসারিত হওয়ার প্রবণতা খুব কম হওয়ায় হঠাৎ থামার সময়, স্ট্যাকিং অপারেশনের সময় বা ভিন্ন পরিবহন মাধ্যমে পণ্য স্থানান্তরের সময় লোডগুলি স্থিতিশীল রাখতে সাহায্য করে। চাপের নিচে প্লাস্টিক প্রসারিত হয়ে যায়, যা আসলে ভবন উপকরণ বা যন্ত্রপাতির মতো ভারী জিনিসপত্রের ক্ষতির সম্ভাবনা বাড়িয়ে দেয়। কম্পোজিট উপকরণগুলি যদিও বেশি নমনীয়তা প্রদান করে, তবু তারা তাদের শক্তি খরচ করে। এক টনের বেশি ওজনের ক্ষেত্রে, বেশিরভাগ পেশাদার এখনও কালো রঙের ইস্পাত বেছে নেন কারণ যেখানে নির্ভরযোগ্যতা সবচেয়ে বেশি গুরুত্বপূর্ণ, সেই বাস্তব পরিস্থিতিতে এটি আরও ভালোভাবে টিকে থাকে।

ক্ষয়, আলট্রাভায়োলেট (UV) রশ্মি এবং পরিবেশগত চাপের বিরুদ্ধে প্রতিরোধ

থার্মোসেট পেইন্টের একটি স্তর উপাদানের ক্ষয়কে রোধ করার জন্য তিনটি স্তরের আবরণ প্রদান করে। গবেষণাগারের পরীক্ষায় দেখা গেছে যে এই পেইন্ট দিয়ে লেপা ইস্পাত 500 ঘন্টার বেশি সময় ধরে লবণাক্ত স্প্রেতে থাকা সত্ত্বেও মরচের কোনও লক্ষণ দেখা যায় না, যা সাধারণ গ্যালভানাইজড ইস্পাতের চেয়ে প্রায় চল্লিশ শতাংশ বেশি টেকসই। পেইন্টে থাকা বিশেষ রঞ্জক পদার্থ ক্ষতিকারক UV রশ্মিকে প্লাস্টিক ভাঙতে বাধা দেয়, তাই মাসের পর মাস বাইরে রাখা সত্ত্বেও কাঠামোগুলি শক্তিশালী থাকে। এই আবরণের সবচেয়ে বড় বৈশিষ্ট্য হল এটি আর্দ্রতা এবং অনেক কারখানাতে পাওয়া যায় এমন ক্ষারীয় রাসায়নিক উভয়কেই বিকর্ষণ করে, যা হাইড্রোজেন ইম্ব্রিটলমেন্টের ঝুঁকি কমায় যা সাধারণত অরক্ষিত ইস্পাতকে দুর্বল করে তোলে। আমরা এই ধরনের টেকসই গুণাগুণ সমুদ্রতীরবর্তী জাহাজ চালান কেন্দ্রগুলিতে, শীতকালে শীতাগার সুবিধাগুলিতে এবং রাসায়নিক কারখানার ভিতরে অন্যান্য উপকরণগুলি কয়েকদিনের মধ্যে ভেঙে পড়ার সময় প্রকৃত পার্থক্য তৈরি করতে দেখেছি।

ভারী-দায়িত্বের শিল্প প্যাকেজিংয়ের জন্য গুরুত্বপূর্ণ অ্যাপ্লিকেশন

উচ্চ-টেনশন স্টিল স্ট্র্যাপিংয়ের মাধ্যমে প্যালেটাইজড লোডগুলি সুরক্ষিত করা

প্যালেটে ভারী লোড নিয়ে কাজ করার সময়, 2000 পাউন্ডের বেশি ওজনের জিনিসপত্রকে স্থিতিশীল রাখতে কালো রঙের ইস্পাতের ফিতা খুবই ভালো কাজ করে। এটি ট্রেন, ট্রাক বা উভয়ের সমন্বয়ে পরিবহনের সময় মালামাল সরে যাওয়া রোধ করতে সাহায্য করে। এই ইস্পাতের শক্তি অসাধারণ, সাধারণ পলিপ্রোপিলিন ফিতার চেয়ে প্রায় তিন গুণ বেশি শক্তিশালী। ইট, টাইলস বা মেশিনের অংশগুলির মতো ভারী জিনিসপত্র নিরাপদে আবদ্ধ করার ক্ষেত্রে এটি অপরিহার্য। প্লাস্টিকের ফিতা দীর্ঘদিন ধরে ভালো কাজ করে না, কারণ টান দেওয়ার পর সেগুলি ঢিলে হয়ে যায়। ইস্পাতের ফিতা পথের ঝাঁকুনি, খাড়া বা তাপমাত্রার পরিবর্তন যাই হোক না কেন, সব সময় দৃঢ় থাকে। দীর্ঘ দূরত্ব ভ্রমণের পর গন্তব্যে পৌঁছানো পর্যন্ত জিনিসপত্র ঠিকভাবে প্যাক করে রাখা যায় এই ধ্রুব চাপ বজায় রাখার মাধ্যমে।

ইস্পাত, কাঠ, কংক্রিট এবং নির্মাণ খাতে শিল্প-নির্দিষ্ট ব্যবহার

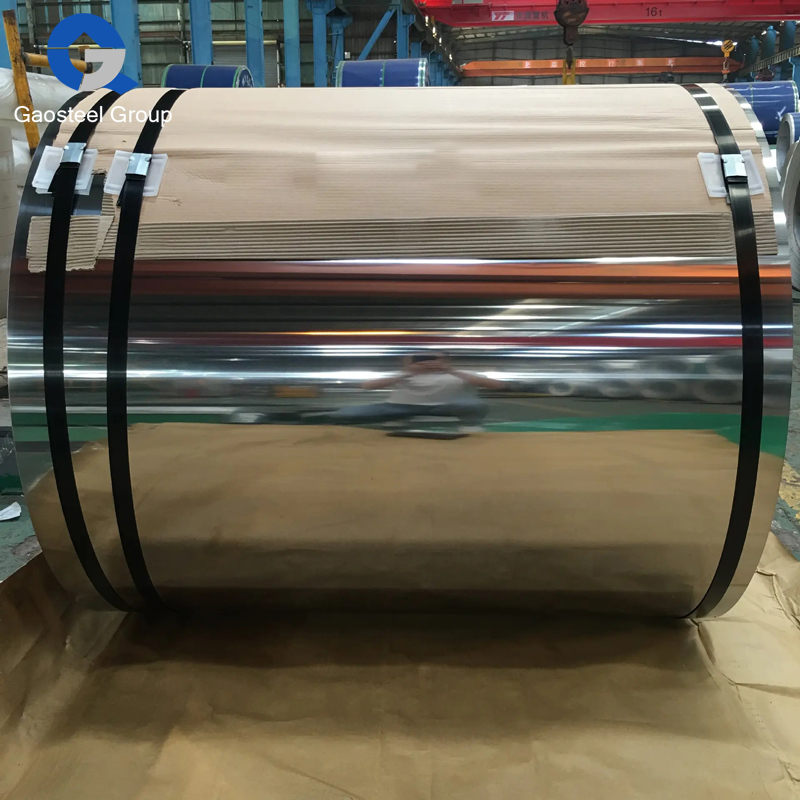

এই স্ট্র্যাপিংয়ের উপর ইস্পাত কারখানাগুলি নির্ভর করে ক্রেন দ্বারা ঘূর্ণায়মান ধাতব পাতগুলি ধরে রাখার জন্য, কারণ এটি তীক্ষ্ণ ধারগুলির বিরুদ্ধে দাঁড়ায় এবং কাটা বা ছিঁড়ে যায় না। কাঠ কোম্পানিগুলিরও এটি প্রয়োজন হয় সবুজ কাঠ এবং চুল্লি-শুষ্ক কাঠের বাঁধাইয়ের জন্য, কারণ সাধারণ জৈব স্ট্র্যাপগুলি এই অতিরিক্ত আর্দ্রতার সংস্পর্শে এসে ভেঙে পড়ে। কংক্রিট নির্মাতারা এটিকে অপরিহার্য মনে করে বৃহৎ প্যানেলগুলি সমান্বয়ের জন্য সম্পূর্ণ শক্ত হওয়ার প্রক্রিয়া চলাকালীন, যেখানে অন্যান্য উপকরণ তাদের ধরণ হারায় বা আবরণ সম্পূর্ণরূপে খসে পড়ে। নির্মাণ ক্রুগুলি বাইরে কাজ করতে পছন্দ করে কারণ এটি UV ক্ষতির প্রতি প্রতিরোধশীল এবং এর দৃঢ় দৃঢ়তা স্ক্যাফিং, পুঞ্জি পুনরাবৃত্তি এবং বাইরে বসা বড় মডিউলার অংশগুলি বাঁধার জন্য আদর্শ, যা মাঝে মাঝে সপ্তাহের পর সপ্তাহ ইনস্টলেশনের জন্য অপেক্ষা করে।

অনিয়মিত, অতিরিক্ত আকার বা উচ্চ-ওজনের শিপিংয়ের জন্য কাস্টম স্ট্র্যাপিং সমাধান

টারবাইন ব্লেড, শিল্প বয়লার বা উইন্ড টাওয়ারের অংশের মতো অ-প্যালেটাইজড, অনিয়মিত বা অতি ভারী লোডের ক্ষেত্রে—কাস্টম-কনফিগার করা কালো রঙের ইস্পাত স্ট্র্যাপিং প্রকৌশলী আবদ্ধকরণ সরবরাহ করে। এর মধ্যে রয়েছে:

- ভঙ্গুর সিলিন্ড্রিক্যাল লোডের জন্য চাপ বন্টনের প্রয়োজন হয় এমন প্রশস্ত-প্রস্থ বৈচিত্র (২" পর্যন্ত)

- ৫ টনের বেশি ওজনের জন্য উপযোগী অতিরিক্ত ঘন গেজ (0.035"+)

- সমুদ্রের কাছাকাছি বা সমুদ্রপথে পরিবহনের জন্য উন্নত ক্ষয়রোধী আবরণ

এই অভিযোজ্যতা বিশ্বব্যাপী সরবরাহ শৃঙ্খলে লোডের অখণ্ডতা নিশ্চিত করার পাশাপাশি ব্যয়বহুল ক্রেটিংয়ের প্রয়োজন দূর করে।

উন্নত শিপিং নিরাপত্তা এবং লোড অখণ্ডতা

দীর্ঘদূরত্ব এবং বহু-আধার পরিবহনের সময় লোডের স্থিতিশীলতা বজায় রাখা

পেইন্ট দিয়ে আবৃত কালো ইস্পাতের ফিতা সমস্ত ধরনের পরিবহন পরিস্থিতিতে মালপত্রের উপর অসাধারণ ধারণ শক্তি প্রদান করে। আমরা ট্রেনের গাড়ি থেকে শুরু করে মহাসাগরের জাহাজ, হাইওয়েতে চলমান ট্রাক এবং এক ধরনের যানবাহন থেকে অন্য ধরনের যানবাহনে মাল স্থানান্তরের মতো জটিল পরিস্থিতির কথা বলছি। এই উপাদানটিকে আলাদা করে তোলে এর অবিশ্বাস্য শক্তি, সাধারণত প্রতি বর্গ ইঞ্চিতে 10,000 পাউন্ডের বেশি, যা প্রায় কোনও প্রসারিত হওয়া ছাড়াই যুক্ত থাকে। এর ফলে তাপমাত্রা তীব্রভাবে পরিবর্তিত হলে, আর্দ্রতা পরিবর্তন হলে বা পরিবহনের সময় ধ্রুবক ধাক্কা লাগলেও প্যাকেজগুলি স্থানে থাকে। প্লাস্টিকের বিকল্পগুলির তুলনায় লোডগুলি খুলে যাওয়ার সমস্যা প্রায় 40 শতাংশ কম হওয়ার কথা লজিস্টিক্স কোম্পানিগুলি জানায়। আরেকটি বড় সুবিধা হল— ইস্পাতের কাঠামো পাত্রগুলিকে উপরে উপরে স্ট্যাক করার সময় চাপা পড়তে বাধা দেয়, যা পৃথিবীর অন্য প্রান্তে পাঠানো দামি পণ্যগুলির ক্ষেত্রে বিশেষ গুরুত্বপূর্ণ।

অননুমোদিত হস্তক্ষেপের চিহ্ন নির্দেশক বৈশিষ্ট্য এবং দৃশ্যমান মনিটরিং সুবিধা

ম্যাট কালো ফিনিশের কারণে সহজেই বোঝা যায় যখন কেউ মালপত্রে হাত দেয় বা অনুমতি ছাড়াই কিছু সরাতে চায়। এই ধরনের হস্তক্ষেপের প্রতিটি চেষ্টাই রং এবং নিচের ইস্পাতের উপরেও স্পষ্ট চিহ্ন রেখে যায়। হালকা রঙের তল বা পুরানো, ক্ষয়ে যাওয়া ফিতাগুলির তুলনায় এটি আলাদা, যা ঘুলিয়ে মিশে যায় এবং পরিদর্শনকে জটিল করে তোলে। বিশেষ থার্মোসেট কোটিং সূর্যের আলোতে ফ্যাকাশেও হয় না, তাই মালপত্র মাসের পর মাস বাইরে থাকলেও ক্ষতিগ্রস্ত অংশগুলি দৃশ্যমান থাকে। নিয়মিত নিরীক্ষার সময় লজিস্টিক্স কর্মীরা এই কালো কোটেড ইস্পাত ব্যবহার করলে প্রায় 30% দ্রুত পরীক্ষা করতে পারেন। এছাড়াও, সাধারণ যন্ত্রপাতি দিয়ে কাটতে না পারায় এগুলি ভাঙতে গুরুতর সরঞ্জাম প্রয়োজন। চোররা যখন তাদের ভাগ্য পরীক্ষা করে, তখন শব্দ তৈরি হয় যা কাছাকাছি কর্মীদের সতর্ক করে তোলে। যেসব পণ্য পরিবহন করা হয় যেখানে প্রতিটি হস্তান্তর ট্র্যাক করা গুরুত্বপূর্ণ, সেখানে পাত্রটিতে এমন নিরাপত্তা নিশ্চিত করা খুবই প্রয়োজনীয়, যাতে পরিবহনের সময় সঠিক রেকর্ড বজায় রাখা যায় এবং নিশ্চিত করা যায় যে বিষয়বস্তুগুলি অক্ষত রয়েছে।

কালো পেইন্ট করা ইস্পাত স্ট্র্যাপিংয়ের দীর্ঘমানের খরচ-কার্যকারিতা

নির্ভরযোগ্য ধাতব স্ট্র্যাপিং ব্যবহার করে প্যাকেজিং ব্যাহত হওয়া এবং পণ্যের ক্ষতি কমানো

খুব ভারী লোড মোকাবেলা করার সময় প্লাস্টিকের বিকল্প হিসাবে কালো পেইন্ট করা ইস্পাত স্ট্র্যাপিং ব্যবহার করলে প্যাকেজিং ব্যাহত হওয়া প্রায় 30% পর্যন্ত কমে যায়। এই উপাদানটি কীভাবে এতটা কার্যকর তা নিয়ে প্রশ্ন আসলে, উত্তর হলো এটি তেমন প্রসারিত হয় না, অপ্রত্যাশিতভাবে ছিঁড়ে যায় না এবং সময়ের সাথে এর টানটান অবস্থা বজায় রাখে। এই বৈশিষ্ট্যগুলি অর্থে কম পণ্য ক্ষতিগ্রস্ত হয়, যা শিল্প মেশিন, নির্মাণ উপকরণ বা সংবেদনশীল যন্ত্রাংশের মতো দামি জিনিস পাঠানোর ক্ষেত্রে অনেক বেশি গুরুত্বপূর্ণ। ইস্পাত উৎপাদন থেকে শুরু করে কংক্রিট উৎপাদন পর্যন্ত বিভিন্ন শিল্পে করা কিছু প্রকৃত ক্ষেত্র পরীক্ষায় আরও কিছু আকর্ষণীয় তথ্য পাওয়া গেছে। যেসব কোম্পানি তাদের স্ট্র্যাপিং পদ্ধতি পরিবর্তন করেছে তাদের ক্ষতির দাবি প্রায় 22% কমে গেছে। দুই হাজার পাউন্ডের বেশি ওজনের জিনিস সরানোর ক্ষেত্রে এই প্রভাব আরও বেশি লক্ষণীয় হয়ে ওঠে, যেখানে প্লাস্টিক আর কাজের যোগ্য থাকে না।

জীবনকালীন খরচ বিশ্লেষণ: ইস্পাত বনাম প্লাস্টিক এবং কম্পোজিট স্ট্র্যাপিং বিকল্প

প্লাস্টিকের স্ট্র্যাপিংয়ের প্রাথমিক খরচ কম হলেও, জীবনকালীন বিশ্লেষণে কালো রঙের ইস্পাতের অর্থনৈতিক সুবিধা স্পষ্টভাবে উঠে আসে:

| খরচ ফ্যাক্টর | প্লাস্টিকের স্ট্র্যাপিং | কম্পোজিট স্ট্র্যাপিং | কালো পেইন্ট করা ইস্পাত |

|---|---|---|---|

| গড় আয়ু | ১২ বছর | ৩-৫ বছর | ১৫+ বছর |

| ব্যর্থতার হার | 18% | 12% | <5% |

| প্রতিস্থাপনের খরচ | উচ্চ | মাঝারি | নগণ্য |

| মোট খরচ/৫ বছর | $14,500 | $9,200 | $4,800 |

ইস্পাত প্রতিস্থাপনের আগে প্রায় দশ বছর স্থায়ী হয়, যার অর্থ বাজারে প্রাপ্য প্লাস্টিকের তুলনা প্রায় 70% কম পরিবর্তন প্রয়োজন। এটি শ্রম খরচ বাঁচায়, উৎপাদন বন্ধ বন্ধ করে এবং অংশগুলি ভেঙে যাওয়ার সময় সেই অতিরিক্ত কাজগুলি কমায়। ইস্পাতে প্রয়োগ করা বিশেষ আবরণ এটিকে আর্দ্রতা এবং কঠোর রাসায়নিকের বিরুদ্ধে প্রতিরোধ ক্ষমতা দেয়, তাই এমন জায়গায়ও এটি শক্ত থাকে যেখানে অন্যান্য উপকরণ ব্যবহার করলে তাদের ব্যবহার শুরুতেই ব্যাঘাত পড়ে। রক্ষণাবেক্ষণ কম ঘন ঘন হয়ে ওঠে নিয়মিত নয়। বড় চিত্রের দিকে তাকালে, কোম্পানিগুলি কালো রঙের ইস্পাত বিকল্প ব্যবহার করে বড় সাশ্রয় পায়। এমন সমস্ত মরামরি বিল যা কখনও পরিশোধ করা হয় না, বীমা দাবি যা ঘটে না এবং অপ্রত্যাশিত বিধ্বংস ছাড়া মানসম্মতভাবে চলমান অপারেশনগুলি নিয়ে চিন্তা করুন। মোটের উপর, ব্যবসায়িক প্রতিবেদন অন্যান্য উপকরণ ব্যবহারের তুলনা সময়ের সাথে সাথে তাদের খরচের প্রায় 40% সাশ্রয় হয়।

কালো রঙের ইস্পাত স্ট্র্যাপিং এফএকিউ

কালো আঁকা ইস্পাতের স্ট্র্যাপিংয়ের টান সহনশীলতা কত?

কালো আলংকৃত ইস্পাতের স্ট্র্যাপিংয়ের গড় টেনসাইল শক্তি 5,000-7,000 PSI, যা প্লাস্টিক এবং কম্পোজিটের বিকল্পগুলির তুলনায় উল্লেখযোগ্যভাবে বেশি।

কালো আলংকৃত ইস্পাতের স্ট্র্যাপিং কীভাবে ক্ষয় প্রতিরোধ করে?

থার্মোসেট পেইন্ট স্তরটি ক্ষয়ের বিরুদ্ধে একটি শক্তিশালী প্রতিরক্ষা প্রদান করে, যা লবণাক্ত স্প্রে পরীক্ষায় 500 ঘন্টারও বেশি সময় ধরে সুরক্ষা দেয়।

ভারী লোডের জন্য প্লাস্টিকের চেয়ে ইস্পাতের স্ট্র্যাপিং কেন পছন্দ করা হয়?

ইস্পাতের স্ট্র্যাপিং কে পছন্দ করা হয় কারণ ভারী লোডের অধীনে এর কম প্রসার্য হার রয়েছে, যা পরিবহনের সময় কার্গোর স্থিতিশীলতা বজায় রাখতে সাহায্য করে।

ইস্পাতের স্ট্র্যাপিং কীভাবে হস্তক্ষেপ-সুবিধাজনক নিরাপত্তা নিশ্চিত করে?

ম্যাট কালো ফিনিশ হস্তক্ষেপকে দৃশ্যমান করে তোলে, এবং পেইন্ট ও ইস্পাত উভয়ের উপরই চেষ্টার চিহ্নগুলি স্পষ্ট হয়ে ওঠে।