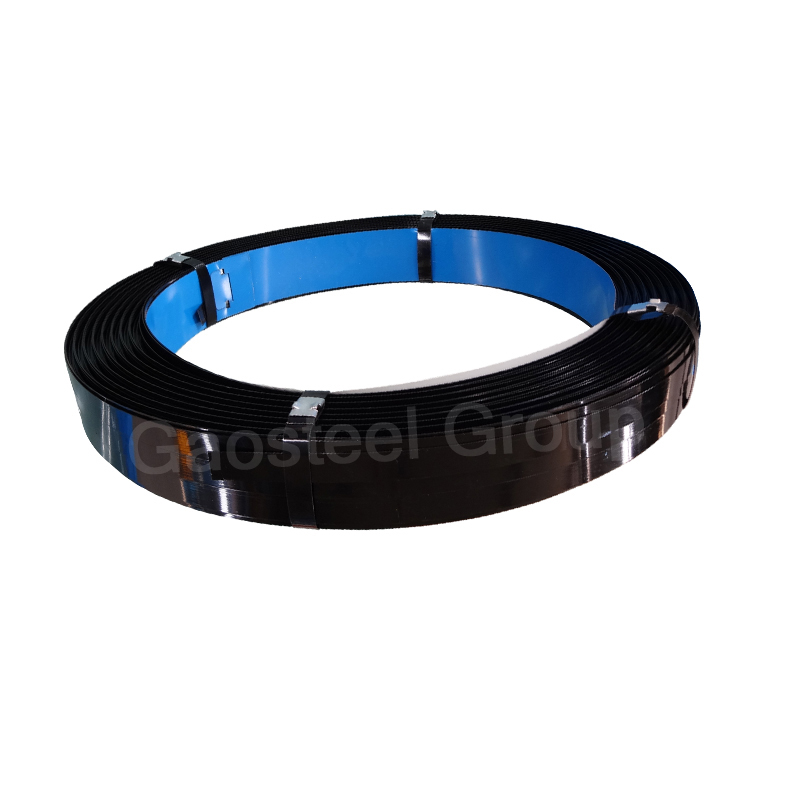

Unmatched Strength of Black Painted Steel Strapping

Understanding the Tensile Strength of Black Painted Steel Strapping

Black painted steel strapping achieves tensile strengths exceeding 50,000 PSI, enabling it to withstand forces 3 times greater than typical plastic strapping. The paint coating reinforces structural integrity rather than compromising it, as stress simulations show coated strapping resists necking 18% longer than uncoated variants during elongation (2024 Steel Strapping Performance Report).

How Steel Grade Impacts Load-Bearing Capacity

High-carbon steel grades (SAE 1070–1095) form the foundation of industrial-grade strapping, with yield strengths between 30,000 and 45,000 PSI. These properties allow a single 0.035" thick – 3/4" wide strap to secure loads over 9,500 lbs—sufficient to restrain three full-sized SUVs on a transport trailer.

Comparative Analysis: Black Painted vs. Galvanized Steel Strapping

| Property | Black Painted Strapping | Galvanized Strapping |

|---|---|---|

| Surface Hardness (HV) | 220–260 | 180–210 |

| Salt Spray Resistance | 500–800 hours | 1,000+ hours |

| Tensile Strength (PSI) | 50,000–60,000 | 38,000–50,000 |

While galvanized coatings offer superior corrosion resistance, black painted variants provide a 12–18% strength advantage, making them ideal for securing heavy machinery during transport.

Case Study: Heavy-Duty Logistics Using High-Tensile Black Painted Strapping

A European heavy machinery manufacturer reduced load failures by 34% after switching to 0.047" gauge black painted strapping. The material successfully withstood 8G shock loads during rail transport—equivalent to the weight of 12 African elephants on a single palletized turbine assembly.

Trend: Increasing Demand for Stronger Strapping in Industrial Automation

The global shift toward automated palletizing systems has driven 22% annual growth in high-strength strapping demand (2024 Industrial Packaging Trends Report). Modern robotic tensioners require materials with ±0.5% elongation—performance specifications consistently met only by steel-based solutions.

Durability, Reusability, and Long-Term Performance

Long-term performance in repetitive use scenarios

Black painted steel strapping endures over 2,000 tension cycles with less than 2% elongation loss (International Materials Review 2023), outperforming polymer alternatives. Its epoxy-polyester hybrid coating prevents micro-crack propagation at stress points, supporting a service life of 8–12 years in daily operations. Regular torque checks every 50 cycles help maintain performance without material degradation.

Resistance to deformation under cyclic stress

With a minimum yield strength of 580 MPa, this strapping retains 98.7% dimensional stability after 10,000 compression cycles—34% better than galvanized equivalents. The tempered steel core absorbs vibrational energy from conveyor systems, minimizing plastic deformation during multimodal shipping. Third-party testing confirms less than 0.3mm permanent bend after simulating 3,000km of truck transport.

Real-world example: reusable strapping in automotive manufacturing

A transmission plant using black painted steel strapping achieved:

- 94% reuse rate across 18 production batches

- €0.11 per-use cost versus €1.73 for disposable alternatives

- Zero load shifts during robotic handling of 2.3-ton engine blocks

The facility’s closed-loop system recovers 99.2% of strapping through automated cleaning and tension recalibration.

Surface Coating and Environmental Resistance

Role of paint coating in corrosion resistance

Black painted steel strapping gets protected from moisture and corrosive stuff thanks to a special coating applied on top. Studies show that when these straps are coated with epoxy mixed with something called polydimethylsiloxane, they resist rust formation much better than regular steel. One recent study found around 72% less rust developing in saltwater conditions after just a few months exposure. What makes this coating work so well is that it actually sticks to the metal at a chemical level, stopping the oxidation process before it starts. Even better, the steel remains strong and durable despite having this extra layer protecting it from environmental damage.

Process of surface preparation before painting

Effective coating adhesion requires thorough surface preparation:

- Degreasing: Removal of oils and contaminants using alkaline solutions

- Abrasive blasting: Achieving a 2.5–3.5 mil surface profile for mechanical bonding

-

Phosphate treatment: Applying zinc or iron phosphate layers to enhance paint adhesion

Industry standards recommend a minimum surface roughness of Ra 50 µin for optimal performance, as specified in marine coating guidelines.

Advantages of black painted finish over bare steel

The painted surface offers 3.8 times better UV resistance and reduces surface friction by 40% compared to bare steel, decreasing cargo slippage during transit. Unlike galvanized finishes, the black coating allows clear visibility of manufacturer markings and simplifies quality inspections.

Industry paradox: painted coatings vs. long-term environmental exposure

While initial testing (ASTM B117) shows 89% corrosion resistance, extended outdoor exposure reveals a 22% degradation rate after five years in industrial zones. Recent research attributes this to micro-crack formation under thermal cycling, with 2024 studies showing hybrid epoxy-polyurethane coatings improve long-term resilience by 51%.

Performance in high-humidity and coastal environments

In 85% relative humidity, black painted strapping retains 94% of its tensile strength after 1,000 hours—significantly outperforming untreated steel at 67%. For coastal applications, specialized coatings resistant to chloride ion penetration are essential, with salt spray tests confirming up to 1,200 hours of protection when combined with proper edge sealing.

Optimal Dimensions: Thickness and Width for Maximum Efficiency

How Dimensions Affect Load Distribution and Joint Integrity

The thickness and width of black painted steel strapping really matters when it comes to how weight gets distributed and how stable those joints stay. When we talk about thicker options ranging from around 0.023 inches to 0.035 inches, they tend to hold their shape better under stress, which means the pressure stays pretty even across all sorts of uneven cargo. For narrower straps between half inch and three quarters of an inch wide, the clamping power focuses right at the connection points. But if someone goes for wider ones measuring one inch up to one and a half inches, there's less risk of damaging sensitive items since the pressure spreads out more along edges. Some research done recently in structural engineering showed that getting the size right can actually boost joint strength by nearly 40 percent for stuff packed onto pallets versus using regular sized strapping.

Optimal Width and Thickness for Different Cargo Types

| Cargo Type | Recommended Width | Ideal Thickness | Key Benefit |

|---|---|---|---|

| Machinery Components | ¾" | 0.030" | Prevents edge slippage |

| Construction Materials | 1¼" | 0.028" | Balances rigidity and flexibility |

| Lightweight Electronics | ½" | 0.020" | Minimizes surface abrasion |

Heavy-duty applications benefit from thicker strapping with 110–150 ksi tensile strength, while thinner gauges are suitable for lightweight, high-volume shipments. Proper dimensional selection reduces material waste by 12–17% annually in bulk logistics.

Industrial Applications and Emerging Use Cases

Key sectors using black painted steel strapping

Black painted steel strapping is used in manufacturing (38% of industrial fastening applications), heavy machinery transport, and aerospace component bundling. Its UV-resistant coating makes it well-suited for outdoor storage in mining logistics and prefabricated construction yards.

Packaging solutions for construction materials

Steel-reinforced concrete panels and structural beams increasingly use black painted strapping due to its 2:1 safety factor over plastic alternatives in lateral load tests. The dark finish provides visual contrast against light-colored materials, reducing inspection time by 15–20% during quality control.

Case study: steel strapping in timber and lumber bundling

A Pacific Northwest lumber processor reduced load failures by 90% after switching to 0.035" thick black painted strapping for Douglas fir bundles. The solution endured 18-month outdoor storage cycles in 80% average humidity without corrosion-related breakages.

Emerging applications in renewable energy component transport

Wind turbine manufacturers now use extra-wide black painted steel strapping to secure 80-meter blade shipments. This aligns with the 22% CAGR forecast for energy sector material handling solutions through 2028, particularly in solar farm structural component logistics.

FAQ Section

What is black painted steel strapping used for?

Black painted steel strapping is primarily used in industrial applications for securing heavy loads during transport, including machinery, construction materials, and renewable energy components.

How does black painted steel strapping compare to galvanized strapping?

Black painted steel strapping offers superior tensile strength but less corrosion resistance compared to galvanized strapping. It is preferred for applications requiring strength over corrosion resistance.

Can black painted steel strapping be reused?

Yes, black painted steel strapping can be reused significantly, with proper maintenance and tension recalibration, supporting sustainable practices in industrial operations.

How does black painted steel strapping perform in coastal environments?

It performs well with specialized coatings that provide resistance to corrosion and chloride ion penetration in high-humidity coastal environments.

Table of Contents

-

Unmatched Strength of Black Painted Steel Strapping

- Understanding the Tensile Strength of Black Painted Steel Strapping

- How Steel Grade Impacts Load-Bearing Capacity

- Comparative Analysis: Black Painted vs. Galvanized Steel Strapping

- Case Study: Heavy-Duty Logistics Using High-Tensile Black Painted Strapping

- Trend: Increasing Demand for Stronger Strapping in Industrial Automation

- Durability, Reusability, and Long-Term Performance

- Surface Coating and Environmental Resistance

- Optimal Dimensions: Thickness and Width for Maximum Efficiency

- Industrial Applications and Emerging Use Cases

- FAQ Section