Types of Roofing Sheets: Materials and Properties

Metal Roofing Sheets: Corrugated, Standing Seam, and Coated Variants

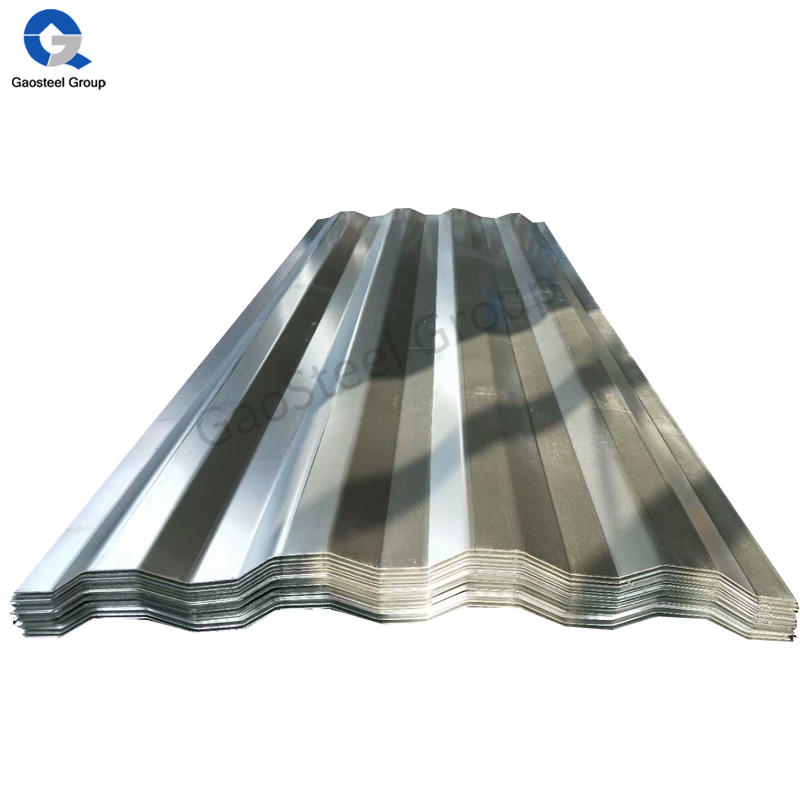

Metal roof panels have become popular choices for homes and businesses because they last long, hold up well, and come in various styles. The corrugated pattern helps rainwater drain off quickly, so these roofs work great in places that get lots of precipitation. Standing seam metal roofs are another option that stands up better against harsh weather conditions, especially when there's snow buildup. Most companies make their metal sheets from galvanized steel about half a millimeter thick, often adding zinc aluminum alloy coatings on top. According to research published by NRC in 2023, this combination can keep a roof functional for anywhere between four decades to almost seventy years under normal weather conditions. For extra protection against fading and rust, manufacturers apply special coatings such as PVDF or polyester. These treatments really help metal roofs withstand the damage caused by salt air in coastal regions where regular corrosion happens much faster than elsewhere.

Polycarbonate, PVC, and Acrylic: Transparent and Lightweight Options

When natural light is needed for spaces like greenhouses, patios or atriums, transparent roofing options including polycarbonate, PVC and acrylic tend to be the go to choice. Polycarbonate really shines when it comes to toughness against impacts, able to take on hailstones measuring around 25mm across according to ASTM standards from 2022. PVC works well as an affordable option for temporary setups, though it does expand more than metal by about 15 to 20 percent which can lead to warping issues over time. These materials all do a decent job blocking most UV rays between 80 and 99 percent, but they generally aren't built for areas that get heavy snowfall since their structural strength isn't quite there for those kinds of loads.

Fibre Cement and Bitumen-Based Sheets: Rigid and Weather-Resistant Solutions

Fibre cement sheets are made from a mix of Portland cement, cellulose fibers and sand, which gives them great fire resistance and keeps their shape even when things get hot. These materials won't warp much in really humid conditions above 85% relative humidity either. They can handle pretty strong winds too, standing up to gusts around 150 miles per hour according to FM Global research from 2021. Bitumen based sheets aren't as tough though. People usually need to replace these every 8 to 12 years in normal weather conditions even though they cost less upfront. When it comes to blocking outside noise, both types work well compared to alternatives like metal panels or polycarbonate sheets. Fibre cement and bitumen products generally cut down on outside sounds between 30 and 50 decibels, making them good choices where quiet is important.

Durability and Lifespan: How Long Do Roofing Sheets Last?

Long-Term Performance of Metal vs. Polycarbonate vs. Fibre Cement

Metal roofs tend to last the longest out there, anywhere between 40 to 70 years depending on how good the coating is and what kind of weather they face daily. Galvanized steel and aluminum versions hold up pretty well against rust, which makes them great choices for coastal areas or places with harsh winters. Polycarbonate sheets are another option, but even with UV protection built in, most start showing their age around 25 to 40 years old with yellow spots appearing or becoming brittle over time. Fibre cement falls somewhere in the middle with a lifespan of about 30 to 50 years. These need regular sealing though to keep water from getting absorbed, something recent tests in 2024 confirmed when looking at different roofing materials' durability under various conditions.

Weather Resistance in Extreme Climates: Heat, Humidity, and Coastal Exposure

Metal sheets coated with zinc-aluminum or PVDF last way longer than regular metal when exposed to salt spray in coastal areas, often standing up to corrosion for over half a century. Polycarbonate works pretty good in those hot, humid tropical places too, though it breaks down about two and a half times quicker when hit by constant UV rays compared with fibre cement options. When temps go above 45 degrees Celsius (which is around 113 Fahrenheit), PVC tends to warp and bend, while fibre cement stays strong because it's made from minerals instead of just plastic compounds. Most contractors know this difference matters a lot when picking materials for different climate zones.

Do Premium Roofing Sheets Always Offer Better Longevity?

Premium materials such as standing seam metal and multi wall polycarbonate tend to last between 15 to 25 years longer than standard corrugated sheets or single layer panels. Interestingly enough, mid grade fiber cement actually holds up pretty well against expensive metal options in areas away from coastal zones, and it costs roughly 40 percent less too. Maintenance matters a lot here though. According to research from Ponemon in 2023, about two thirds of how these materials perform in actual use comes down to regular upkeep rather than just what was installed initially. So when thinking about long term savings, remember that proper care makes almost as big a difference as choosing the right material in the first place.

Cost Analysis: Initial Price vs. Long-Term Value of Roofing Sheets

Budget-Friendly Metal and Polymer Options for Cost-Sensitive Projects

Galvanized corrugated steel stands out as an affordable metal choice, typically running between two to five dollars per square foot and lasting anywhere from twenty five to forty years. When money is really tight, folks often turn to PVC or polycarbonate sheets which usually come in at around twenty to thirty percent cheaper than metal options. The catch? These plastic materials don't last quite as long, generally giving about fifteen to twenty five years of service. And here's something important for those living in damp areas: polymer roofing can actually end up costing more in the long run. Mold becomes a real problem in humid conditions, requiring regular treatments that might set homeowners back fifty cents to a dollar fifty per square foot each year. What starts as a budget friendly solution ends up eating into those initial savings pretty quickly.

Total Cost of Ownership: Maintenance, Repairs, and Replacement Cycles

Metal roofs tend to save money over time because they need so much less maintenance and repair work. Compared to other materials, metal needs about 60 percent less upkeep when looking at fiber cement options, and around 45 percent fewer repairs than those old bitumen systems most people still use. When it comes to actual costs, recoating metal surfaces roughly every 15 to 20 years runs between $1.20 and $2.80 per square foot. That's way cheaper than what happens with polymer sheets that degrade over time. Replacing those usually costs anywhere from $4.70 to $6.30 per square foot after about twenty years. And there's an extra bonus too. Metal roofs with solar reflective coatings can actually cut down on cooling expenses by somewhere between 12 and 18 percent in really hot areas, which makes them even more attractive for homeowners concerned about both their wallets and energy bills.

Best Roofing Sheet by Application: Residential, Industrial, and Garden Use

Residential Roofs: Aesthetics, Noise Control, and Durability

Many homeowners go for color coated metal roofs because they look great, and there are actually around 25 different finishes to pick from that can blend with just about any house design. Something interesting about these coated metals? They cut down on rain noise by about 40 percent when compared to regular metal sheets according to the Building Materials Report from last year. Fibre cement tiles are pretty popular too, especially where fires might be a concern or places that get lots of moisture. These materials resist flames naturally, don't need much upkeep, and won't rust away even after years of exposure to damp air.

Industrial and Agricultural Buildings: Strength, Span, and Corrosion Resistance

Steel sheets coated with PVC can span distances of around 12 meters without needing extra framing structures. These materials also stand up well against chemicals and saltwater, making them especially useful in areas near the coast where corrosion is a big concern. For agricultural buildings, there's been a growing trend toward using steel with aluminum zinc alloy coatings. This type of steel tends to last about two to three times longer than regular galvanized iron when exposed to humidity. Plus it absorbs significantly less heat compared to traditional options, cutting down on heat gain inside the building by roughly 35%. The result? Better temperature regulation within these structures, which translates to real world savings for farmers and building operators alike.

Garden Structures and Greenhouses: Lightweight, Transparent Polycarbonate Solutions

When it comes to greenhouses and outdoor garden buildings, polycarbonate panels have become the material of choice for many growers. These panels let through around 90% of daylight but stop almost all harmful UV rays from getting through. What makes them stand out is their unique honeycomb structure inside, which gives them about triple the strength against impacts compared to regular glass, yet they're only about 20% of the weight. For even better temperature control, twin wall versions work wonders. They cut down on heat loss by roughly half when compared to standard acrylic sheets, so plants stay warm in winter without losing that precious sunlight during the day. Gardeners love how these panels keep things consistent year round.

Choosing the Right Roofing Sheet for Climate and Environmental Conditions

Optimal Roofing Sheets for Hot, Humid, and Coastal Climates

When it comes to areas where it gets really hot, damp, and close to the coast, roofing materials need to stand up against corrosion, UV damage, and water soaking in. Metal sheets that have been coated with zinc-aluminum blends or PVDF coatings tend to last way longer in salty air than regular metal without these protective layers according to industry reports from around 2023. Some studies suggest they might actually hold out about three to four times better against rusting out. Fibre cement is another good option because it handles high humidity pretty well. Since it's made from non-organic stuff, it doesn't get moldy or warp when temperatures fluctuate too much. Looking at passive cooling solutions, those UV stabilized polycarbonate sheets make a big difference too. They cut down on heat buildup inside buildings by roughly half compared with old fashioned asphalt shingles, though results can vary depending on installation quality and local climate conditions.

Performance in Rainy and Temperature-Variable Regions

In regions where rain falls heavily or freeze-thaw cycles are common, roofs need to stay completely sealed against water and handle all sorts of temperature changes without failing. Standing seam metal roofs work really well in these conditions because their panels lock together tightly, keeping water out even when it's pouring down at over 10 inches per hour straight from the sky. For sloped roofs facing those intense monsoons, fiberglass reinforced bitumen sheets offer solid protection against leaks. And then there's polycarbonate material which holds up remarkably well through extreme temperatures ranging from as low as minus 40 degrees Fahrenheit right up to 240 degrees without showing any signs of cracking or becoming cloudy over time.

Material Stability: Managing Thermal Expansion and UV Degradation

Roofing materials all tend to expand when it gets warm and shrink when temperatures drop, though metal sheets coated with baked-on finishes restrict this movement to around 0.15 inches for every 10 degree Fahrenheit change. That helps keep stress off those fastening points which can be a big problem otherwise. Things get worse for unprotected polycarbonate and PVC materials that sit out in direct sun. These materials actually lose between 30 to 50 percent of their tensile strength just 5 to 7 years after installation because of constant UV exposure. Fibre cement tells a different story entirely. This material stays pretty much the same size over time, keeping about 95% of its original strength even after spending 25 years under intense tropical sunlight according to the Building Materials Durability Report from 2023. When looking at materials for lasting performance, builders should focus on options where thermal expansion rates stay under 5 micrometers per meter per degree Celsius. Such materials simply handle temperature fluctuations better in the long run.

FAQ

What are the advantages of using metal roofing sheets?

Metal roofing sheets offer longevity and durability, with a lifespan of 40 to 70 years. They resist rust and weathering, making them ideal for coastal areas and regions with harsh weather conditions. Additionally, coated metal sheets can reduce noise and are cost-effective in the long-term.

Are polycarbonate sheets suitable for areas with heavy snowfall?

Polycarbonate sheets are not recommended for areas with heavy snowfall due to their structural limitations. They are best used where transparency and lightweight materials are desired, such as greenhouses, patios, and atriums.

How do fibre cement sheets compare to bitumen sheets?

Fibre cement sheets are more robust than bitumen sheets, offering better resistance to fire and high humidity. While bitumen sheets are cheaper upfront, they typically need replacement within 8 to 12 years, whereas fibre cement sheets last considerably longer.

Which roofing materials are best for hot and humid climates?

For hot and humid climates, metal sheets with zinc-aluminum or PVDF coatings are recommended for their superior corrosion resistance. Fibre cement sheets are also suitable due to their stability in high humidity.

Can roofing material affect cooling expenses?

Yes, materials like metal roofing with solar reflective coatings can reduce cooling expenses by 12-18% in hot climates, making them an energy-efficient option.

Table of Contents

- Types of Roofing Sheets: Materials and Properties

- Durability and Lifespan: How Long Do Roofing Sheets Last?

- Cost Analysis: Initial Price vs. Long-Term Value of Roofing Sheets

- Best Roofing Sheet by Application: Residential, Industrial, and Garden Use

- Choosing the Right Roofing Sheet for Climate and Environmental Conditions

- Optimal Roofing Sheets for Hot, Humid, and Coastal Climates

- Performance in Rainy and Temperature-Variable Regions

- Material Stability: Managing Thermal Expansion and UV Degradation

- FAQ