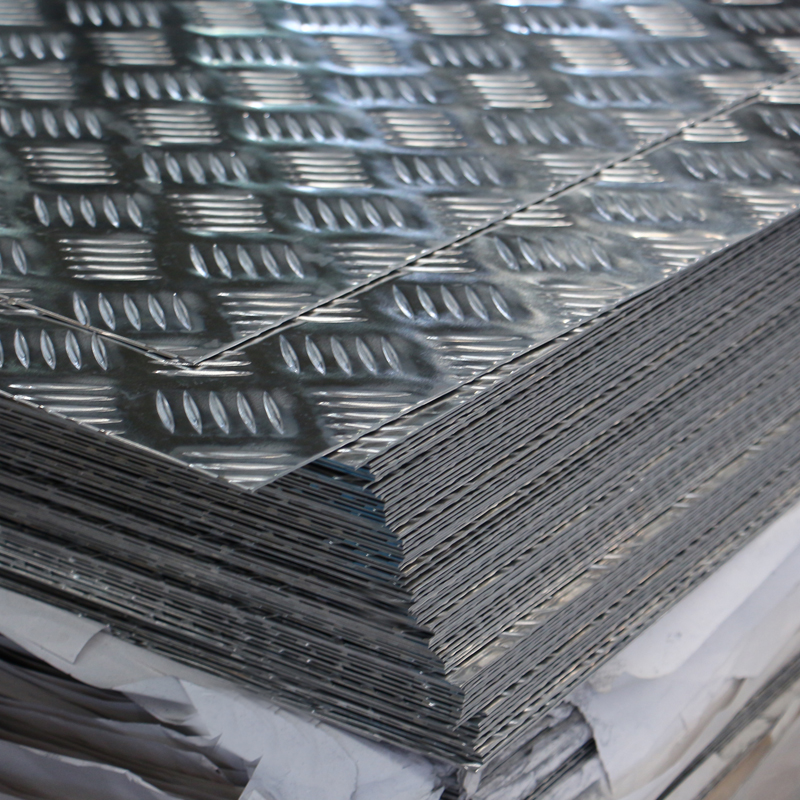

Superior Safety: Anti-Slip Performance of Aluminum Checker Plate

How Tread Pattern Geometry Enhances Traction and Reduces Slip Risk

Aluminum checker plate with its distinctive diamond pattern actually works by creating tiny areas of friction across the surface, making it much grippier than smooth metal. Those angled treads we see at around 35 to 45 degrees do double duty they help push water off walkways while also providing resistance when someone tries to slide across them. Research from the National Floor Safety Institute shows these kinds of tread designs cut down slip accidents by almost half in factories and warehouses where floors get wet. And this matters because slipping remains the top reason workers end up falling on the job, responsible for roughly 60 percent of all such incidents according to their latest data from 2023.

Meeting Safety Standards: ASTM F2945 Compliance in Industrial Applications

Aluminum checker plate made for industrial use meets the ASTM F2945 standard which is all about creating high traction walking surfaces. These plates actually reach a dynamic coefficient of friction (CoF) over 0.5 even when wet, making them pretty good at preventing slips. Plants that work with oils, chemicals, or process food find these surfaces really helpful since they stay secure despite spills and messes. According to the 2024 Industrial Safety Benchmark Report, workplaces switching to these certified plates saw around 70% drop in those OSHA recorded slip accidents. Plus there's the added bonus of being non sparking, so they're safer to use in areas where explosions could happen from static electricity buildup.

Balancing Grip and Functionality: Diamond Pattern Density vs. Drainage and Cleanability

Pattern density directly influences both safety performance and long-term maintainability:

| Diamond Density | Traction Level | Drainage Speed | Debris Cleanability | Best Applications |

|---|---|---|---|---|

| High (5-bar) | Extreme | Moderate | Challenging | Oil rigs, heavy machinery platforms |

| Medium (standard) | High | Fast | Easy | Factory floors, loading docks |

| Low (lentil) | Moderate | Very fast | Excellent | Commercial kitchens, pool decks |

Higher-density patterns maximize slip resistance but demand more frequent cleaning; spaced configurations prioritize rapid drainage and hygiene—critical in food processing or high-moisture settings. Engineers can therefore select the optimal balance based on site-specific risk profiles and operational needs.

Long-Term Durability: Corrosion Resistance of Aluminum Checker Plate

The Role of the Natural Oxide Layer in Harsh and Coastal Environments

Aluminum checker plate fights off corrosion thanks to an oxide layer that forms almost immediately when exposed to oxygen. What makes this protection special is how it heals itself when scratched, stopping things like saltwater, harsh chemicals, and regular humidity from getting through. Tests done over fifteen years at coastal locations show pit damage stays below 0.1mm, which means this material stands up really well in places like marine docks and chemical processing facilities. Maintenance teams don't have to keep spending money on removing rust and repainting surfaces anymore. And here's another plus point: the protective coating doesn't break down even in super cold conditions down to -50 degrees Celsius or hot environments reaching 150 degrees Celsius. While regular steel would start to fail under these extremes, aluminum checker plate keeps its strength intact without needing constant repairs.

Comparing Alloy Performance: 3003, 5052, and 6061 in Salt Spray and Load Tests (ASTM B117)

Under ASTM B117 accelerated corrosion testing, different aluminum alloys deliver distinct performance advantages:

- 3003: Withstands 1,000+ hours of salt spray—ideal for indoor or mildly corrosive environments like warehouse platforms.

- 5052: Excels in marine applications, resisting over 3,000 hours of salt exposure while retaining ductility for bent components such as boat ramps.

- 6061: Offers superior strength-to-weight balance with magnesium-silicon reinforcement, enduring 2,500 hours in salt spray—suited for heavy-load structures requiring both load capacity and corrosion resistance.

Testing confirms 5052 retains 95% of its tensile strength after prolonged salt immersion—outperforming carbon steel by 400% in corrosion resistance without adding weight penalties.

Efficient Construction: Lightweight Strength and Fabrication Advantages

Aluminum checker plate offers impressive structural performance, weighing around 33% less than similar steel plates but still holding up under the same loads. The lighter weight makes installation much easier for workers who can handle the sheets without heavy machinery, which means projects get finished faster too. Some studies from last year showed construction times improved by about 25%. With less weight to support, there's naturally less strain on foundations and framing systems, saving money on those components. Another big plus is how easy it is to work with aluminum during fabrication processes. Cutting, drilling, and welding all go smoother compared to steel, giving contractors more flexibility when things don't go exactly according to plan on site. All these factors combined explain why many builders are turning to aluminum checker plate when they need materials that save time, cut costs, and still stand up to whatever conditions throw their way.

FAQ

What makes aluminum checker plate anti-slip?

The diamond pattern creates friction points that enhance grip, while angled treads help push water off surfaces.

How does aluminum checker plate meet industrial safety standards?

These plates comply with ASTM F2945 standards, reaching a dynamic coefficient of friction over 0.5, even when wet.

How does aluminum checker plate resist corrosion?

An oxide layer forms on aluminum, repairing itself when scratched to prevent corrosion from saltwater, chemicals, and moisture.

What are the advantages of aluminum checker plate in construction?

Lightweight yet strong, aluminum checker plate simplifies installation and saves time and costs in construction projects.

Table of Contents

-

Superior Safety: Anti-Slip Performance of Aluminum Checker Plate

- How Tread Pattern Geometry Enhances Traction and Reduces Slip Risk

- Meeting Safety Standards: ASTM F2945 Compliance in Industrial Applications

- Balancing Grip and Functionality: Diamond Pattern Density vs. Drainage and Cleanability

- Long-Term Durability: Corrosion Resistance of Aluminum Checker Plate

- Efficient Construction: Lightweight Strength and Fabrication Advantages

- FAQ