Why Galvanized Steel Strip Is Essential for Modern Packaging

Rising Demand for Durable and Reliable Packaging Materials

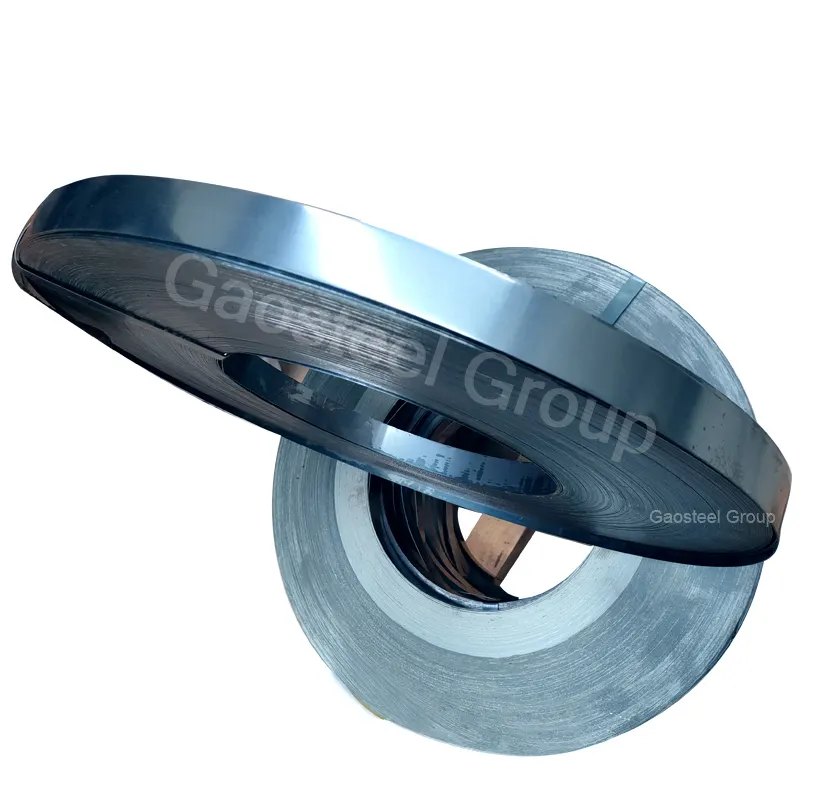

Food production, automotive manufacturing, and construction all need packaging that can handle rough transportation, long-term storage, and frequent handling without failing. Most manufacturers these days are really focused on finding materials that resist corrosion better while still holding up under weight. Damaged products cost money, so companies are paying extra attention to this aspect. Galvanized steel strips have become popular because they're light but strong enough to handle serious stress. These strips boast tensile strength well above 550 MPa which makes them great for wrapping around heavy machinery parts or protecting delicate pharmaceutical products during shipping. The combination of durability and manageable weight has made galvanized steel a go-to solution across multiple industries facing tough logistics challenges.

How Galvanized Steel Strip Enhances Structural Integrity and Protection

Galvanized steel strips have a zinc coating that acts as protection from moisture, stops oxidation, and resists wear and tear. When it comes to packaging, this means products last longer on store shelves because there's no risk of rust getting into food containers. The structural integrity also stays intact when goods are stacked on pallets during transport. Take galvanized strapping for instance. Logistics reports from 2023 show that shipments using this type of strapping fail about 23 percent less often than those wrapped with plastic alternatives, especially important in areas where humidity is high. This makes a real difference in keeping products safe throughout their journey from factory to customer.

Trend: Shift Toward Sustainable and Reusable Industrial Packaging

Around 78 percent of Fortune 500 firms have set their sights on zero waste, which makes sense given how galvanized steel strips actually help move toward those circular economy objectives. Take them versus regular plastic stuff we throw away all the time these days. Steel strips get used again and again about twelve times before they're ready for recycling, and best part? No drop in quality during that process. Big online retailers are switching from traditional wooden pallets to these collapsible steel crates made from galvanized material. The switch cuts down on packaging trash by roughly 34% each year according to recent studies. Plus, since these crates last well over fifteen years, businesses still see good returns on investment despite initial costs being higher than wood alternatives.

Superior Corrosion Resistance and Long-Term Durability

Understanding Corrosion Protection in Galvanized Steel Strip

Steel strips coated with zinc get their protection against rust because of this zinc layer that serves two purposes at once. First, it physically blocks corrosive elements from reaching the steel underneath. Second, when exposed to air and water, the zinc creates a protective oxide film that stops the steel from oxidizing. What makes galvanized steel really effective is what happens when there are scratches or damage points. The zinc around those areas actually starts to corrode first instead of the steel itself. This special property is known in engineering circles as cathodic protection. Because of this self-sacrificing behavior, galvanized steel can resist rust formation for years even when faced with challenging conditions such as high humidity levels or polluted industrial air.

Performance in Harsh Environmental Conditions

Galvanized steel strip holds up remarkably well even when exposed to harsh environments, whether it's near salty coastlines or inside factories where chemicals are constantly present. The protective zinc layer can handle pretty much anything thrown at it, surviving temperatures as low as minus 40 degrees Celsius all the way up to around 200 degrees without showing signs of damage like cracks or peeling. This makes galvanized steel especially good for products that need protection in unpredictable weather conditions. Tests conducted over many years have found that these coatings keep about 85% of their original thickness after two decades sitting outside in normal climates, which beats most painted surfaces or plastic coatings hands down when there's lots of humidity around.

Galvanized vs. Non-Galvanized Steel: A Durability Comparison

Steel that isn't galvanized starts showing signs of corrosion pretty quickly after getting wet, often within just a few months. Galvanized steel stands up much better though, lasting around 10 to 15 years before needing any kind of maintenance under similar weather conditions. When it comes to packaging materials specifically, companies see their replacement schedules drop by roughly 60 to 70 percent when switching to galvanized options. The International Zinc Association released some findings last year from their lifecycle study on packaging materials. According to their research, using galvanized steel strips actually cut down overall packaging expenses by about 22% over ten years when compared against regular untreated steel. This cost savings happens mainly because there are far fewer repairs needed and the material simply lasts longer in service.

Cost-Effectiveness Across the Packaging Lifecycle

Initial Investment vs. Long-Term Savings with Galvanized Steel Strip

Galvanized steel strip costs about 15 to 20 percent more initially than regular steel options, but it actually saves money in the long run. According to Steel Packaging Institute data from 2023, companies typically see around 30% savings on overall costs within just five years. The zinc layer acts as protection against rust and corrosion, so these strips hold up much better when exposed to moisture or harsh chemicals. Industrial facilities have noticed this benefit firsthand. A recent survey found that nearly 8 out of 10 businesses saw their packaging last between three and five extra years once they made the switch to galvanized materials. Fewer replacements mean less downtime and maintenance headaches for operations managers dealing with inventory issues.

Reducing Maintenance, Replacement, and Downtime Costs

Industries lose around 740 million dollars every year because of packaging failures caused by corrosion according to NACE data from 2023. Galvanized steel strips help reduce these problems thanks to their even zinc coating that's typically over 50 microns thick. This kind of protection cuts down on how often maintenance needs to happen by about 60 percent when materials are stored or transported outdoors. The savings really add up since downtime tends to cost three times what actual repairs do. These steel strips perform reliably across extreme temperatures ranging from minus 40 degrees Celsius all the way up to 120 degrees, plus they hold up against UV damage too. Warehouses that handle fast moving goods find this particularly valuable as it lets them maintain leaner inventories without worrying about unexpected restocking due to failed packaging.

Versatile Applications Across Key Packaging Sectors

Use of Galvanized Steel Strip in Food, Automotive, and Construction Packaging

Galvanized steel strip is changing how packaging works in several demanding industries because it combines toughness with good weather resistance. For food products, the zinc layer stops rust from forming inside packages, something that keeps things clean and safe. Market reports coming out around 2025 point toward metals becoming increasingly important for keeping food safe during storage and transport. Car makers have started using these steel strips to pack sensitive parts like engines and delicate electronic components. The material absorbs shocks pretty well and keeps moisture away while parts are being shipped around. Construction companies also find value in reinforced steel strip packaging when moving large machine parts between sites. When shipments arrive intact without damage, everyone saves money and time on repairs or replacements down the road.

Custom Packaging Solutions: Flexibility and Design Adaptability

Galvanized steel strips are pretty flexible stuff, which means packaging engineers can really customize them for those tough-to-pack products nobody else seems to handle. The thickness ranges anywhere between 0.15mm all the way up to 2.0mm depending on what's needed for strength versus how heavy the package should be. And there are these special coatings available now too, like ones without chromate that meet all sorts of regulatory standards across different industries. This kind of flexibility becomes super important when dealing with weird shapes such as parts used in airplanes or医疗器机. When something fits exactly around an object, it just doesn't move around inside during transport, so nothing gets damaged along the way.

Balancing Strength and Weight in Industrial Packaging Design

New galvanization methods produce steel strips capable of reaching around 550 MPa tensile strength while still cutting down on weight by about 15 to 20 percent when compared with regular steel options. The improved strength to weight balance means logistics folks can save money on transportation without sacrificing cargo protection, something that matters more every year as shipping prices climb roughly 8% each year according to World Bank reports from last year. When it comes to things packed on pallets, those reinforced corners made with these special steel strips cut down on crushed packages during testing by almost half, which shows just how much they help keep products safe throughout transport.

Choosing the Right Type of Galvanized Steel Strip for Packaging Needs

Electro-Galvanized vs. Hot-Dip Galvanized Steel: Pros and Applications

Steel strips that are electro galvanized get their protective layer through an electrolytic process, which deposits about 3 to 12 microns of zinc onto the surface. These work pretty well for things like indoor packaging where only basic protection against rust is needed. For tougher conditions though, hot dip galvanization is the way to go. When manufacturers dunk steel into molten zinc baths, they end up with coatings around 45 to 85 microns thick. This makes them much better suited for harsher environments like coastal areas or places with lots of moisture. The cost savings from electro galvanizing can be anywhere between 15% and 20%, but when it comes to how long these materials last in wet climates, hot dip treated steel often lasts almost twice as long as its electro galvanized counterparts.

Benefits of Continuous Galvanization and Uniform Coating

Continuous galvanization processes ensure consistent zinc layers without weak spots, critical for high-stress packaging like automotive part containment. Uniform coatings prevent premature rusting and reduce material waste by 8–12% during manufacturing, supporting sustainable packaging initiatives.

Matching Steel Strip Type to Specific Packaging Requirements

Food-grade packaging mandates FDA-compliant zinc coatings, while construction materials prioritize tensile strength (>550 MPa). For lightweight yet durable solutions, 0.4mm galvanized strips with 20g/m² zinc coatings balance structural integrity and cost savings.

FAQ Section

What makes galvanized steel strip an ideal choice for packaging?

Galvanized steel strip is known for its strength, durability, and resistance to corrosion, making it ideal for packaging that requires structural integrity and protection from external elements.

How does galvanized steel strip contribute to sustainability in packaging?

Galvanized steel strips can be reused multiple times and are recyclable, which reduces packaging waste and supports circular economy goals.

What are the differences between electro-galvanized and hot-dip galvanized steel strips?

Electro-galvanized strips have a thinner zinc coating suitable for indoor use, while hot-dip galvanized strips have thicker coatings ideal for harsh, outdoor, or coastal environments.

What industries benefit most from using galvanized steel strips?

Industries such as food production, automotive, and construction benefit significantly from using galvanized steel strips due to their strength and ability to resist environmental damage.

Is there a difference in cost-effectiveness between galvanized and non-galvanized steel?

While galvanized steel may have a higher initial cost, it offers long-term savings due to reduced maintenance, replacements, and increased durability.

Table of Contents

- Why Galvanized Steel Strip Is Essential for Modern Packaging

- Superior Corrosion Resistance and Long-Term Durability

- Cost-Effectiveness Across the Packaging Lifecycle

- Versatile Applications Across Key Packaging Sectors

- Choosing the Right Type of Galvanized Steel Strip for Packaging Needs

-

FAQ Section

- What makes galvanized steel strip an ideal choice for packaging?

- How does galvanized steel strip contribute to sustainability in packaging?

- What are the differences between electro-galvanized and hot-dip galvanized steel strips?

- What industries benefit most from using galvanized steel strips?

- Is there a difference in cost-effectiveness between galvanized and non-galvanized steel?