Fahimtar Matsalar Fulani na Carbon: Siffo da Nau'oi

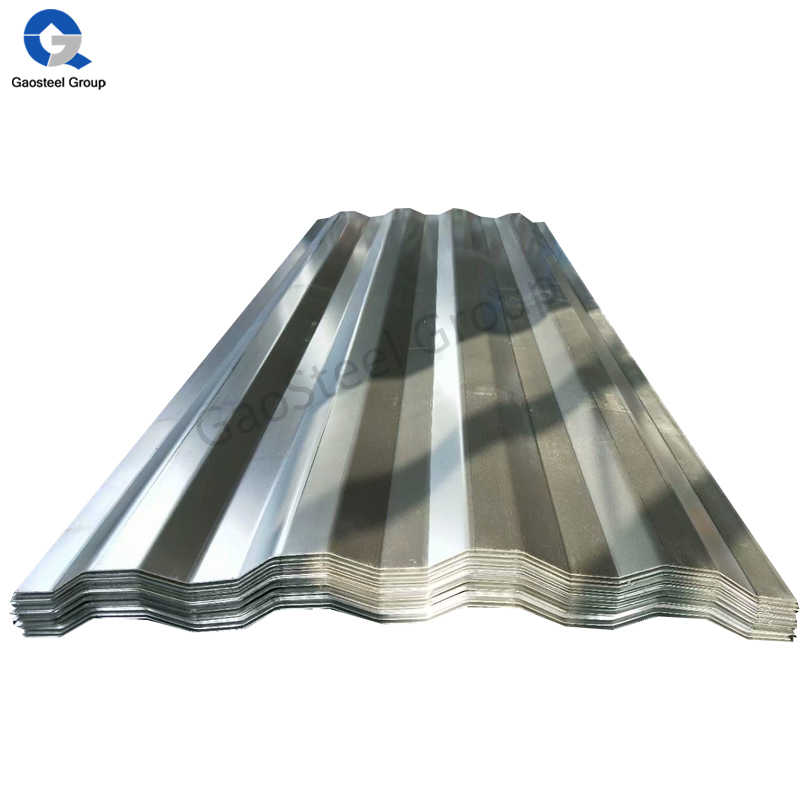

Matsalar fulani na carbon suna da matsala na amfani da kama, samuwar aiki da biyan, wanda ke nufin ake amfani dashi a cikin tsarin da samfurorin girma. Aikin sune da kevuri na carbon da tsarin yin aiki, wanda ke nufin yin aiki da amfani.

Siffo Na Musa na Matsalar Fulani na Carbon (Kama, Samuwar Aiki, Biyan Da Ake Amfani Dasu)

- Rabuwa : Kama na tensile ya tsaya daga 400–1,000 MPa ba da kama na carbon

- Samuwar aiki : Masu ƙarin karbon (≤0.3% karbon) zaba cuttin da welding ta hanyar alama masu amfani

- Sabunta Da Sabon : 30–50% mafi sanyi ne dibu mai tashar karbon kuma yana da saukin tsaya

Maganin Dangamashin Karbon da Saiyen Masu Tsara

Ƙarin karbon yana ninki kuma yana zin fitsoniya-a wani abu mai muhimman kwallon aikin. Masu karbon mai daraja (0.3–0.6% karbon) zaban saukin gudun 570–850 MPa, bamain su ne don riga da shafts da su ne za ake amfani da su a cikin abin da ke jin kuskurewar. Masu tsara yana amfani da wannan taka leda a lokacin da suka rarraba abubuwa da ke jin kuskurewar ko mai girma.

Nau’o’i na Plaitun Karbon: Sanyi, Mada, da Karmon Karbi

| Mai Karbon | Karakitin Kullum | Matsayin da ake amfani da su |

|---|---|---|

| 0.05â≤0.3% | Mai girma mai fitsoniya, mai welding | Masu tsara gida, masu riga |

| 0.3â0.6% | Tsarin asra/tsarin ƙaddamarwa | Ƙayayyen na otomatik, abubuwan masinu |

| 0.6â2.1% | Kankanta da tsawon, zuwa da kankanta | Alamun cut, alamun gani, alamun tashar da aka fi ƙarfi |

An gama ƙanan da ke da karfin gudun lowa yayin da suka da saukin amfani, amma suka biyu da karfin gudun high-carbon wanda aka sami su a cikin ma'ana da aka fi zuwa da kankanta.

Inqar A36 kaiwa gida daga ASTM

Zaftin da ake so don aiki na tsari

An samun ƙayyar gudun ASTM A36 za su zama abin da ake amfani da shi ne don aikin tsari saboda suka tsara saukin ƙafa da kudin da saukin gyara. Mai kyau a cikin wadannan abu ne suka da karfin gudun (ƙasa da 0.29%), haka ya sa su da ba su hanyar amfani da saukin gyara ba wanda aka fassara a cikin Science Bulletin.

Saukin ƙafa da alhakin gyara a cikin ƙayayyen gudun karfi

Yadda karfin gudun ya ke ƙasa da saukin ƙafa a cikin low, medium, da high carbon steel plates

Fayyen karbon guda mai karbon dogon yana welds da karkashin daya kafin hada da kusurwa. Wannan nau'ikan yana da kyau don gudanƙar jiki kuma bata buƙatar tazara a gaban welds. Don karbon a ƙarƙashin 0.60%, matsalar karburwa suna zama abin taka.

Preheating da Post-Weld Treatments don Fabrication mai tsauri

Bayan kama da welds, sake naka karamin cikin 1,000°F yana ƙarin karamin jiki. Preheating steels a cikin 0.3% da 0.6% karbon kake kula da thermal gradients wanda zai iya hada da warping ko cracking.

Taka leda madaida, strength, da Corrosion Resistance a cikin Material Selection

Sabon tallafin steel ya kamata ya yi hisabta da abin da aka yi gudanƙar jiki, hanyar tushen kan environment mai karburwa, da lokacin da ake buƙata tsauri. Low carbon steels sune da coating don taka leda a cikin environments mai karburwa, amma karbon mai tsawon yana amfani da shi don taka leda mai karburwa kuma yana dogon karamin jiki.

Zaƙƙakun farko: Bukatun Carbon Steel Plates

A ƙidaya ta 2021 na dandalin Littattafan Nassarawa ta gani cewa platun fayilin ASTM A572 Grade 50 ya kawo ingancin ingancin a cikin tsarin rig ya yi harcin ingancin biyu da 18%, wanda ya faru da muhimmiyar su ne don wellheads na zazzabi da kuma suporta na rig. Siffofin abubuwan da suka fito ya kawo ingancin ingancin a cikin yankunan da suka tabuta.

Sashen Tambayoyi

Mene ne siffofin muhimmin platun fayilin?

Platun fayilin aka sami su a matsayin ƙima, cuta da kuma tattara sabon biyan kuɗi. Suna da tsangayar ƙima da ke tafiya daga 400 zuwa 1,000 MPa ba da kama ne carbon na su. Variantolin fayilin da ke ƙarin 0.3% carbon suna da cuta da kuma welding mai sauri a kai tsakanin alama, kuma suna da biyan kuɗi 30-50% darasin biyan kuɗin stainless steel bayan kama da kai'iddon jiki.

Mene ne zaɓi ɗaya daban-daban na platun fayilin?

Za a iya kategorizuwa fassarar karbon na fahita da suke based on karboni da suke: kara (0.05–0.3%), mai tsere (0.3–0.6%), da kuma karboni mai yawa (0.6–2.1%) variants. Kowane no da suke da alaƙa da gaskiya da amfani guda biyu kamar yadda suke da ƙarƙashin gine-ginen da suke don karboni mai tsere, abubuwan gurbin na mota don karboni mai tsere, da kuma alamomin cuttina don karboni mai yawa.

Mene ne peshi ne ASTM A36 ya zafin zaɓin gine-ginen?

ASTM A36 ya sami shidda da keɗe na ƙwararri, tattara da kwararri, da biyan kudi, ya sa su ziyar da zaɓin gine-ginen kamar yadda suke da ƙarƙashin. Karboni mai tsere ya kara ƙarin preheating lokacin tattara kuma ya bace tare da tattara da kewayon gudun.

Yaya ne karboni ya ke fassarar tattara da kewayon gudun na karba?

Fayilin kankara mai ƙaranci (zuwa ƙarshen 0.3%) ya da shi da ingantaccen inganci kuma bata ba muhimmi a mutuwar gishin lokacin gishin, ya da shi da taimakon taka ba tushen cikin girma. Steels na kankara ta mutuwar ya kamata taka lele na mutuwar gishin don hana taka ba mutuwar, amma steels na kankara mai girma suke da kyauyar girma kuma suke da shakka ta hanyar taka ba mutuwar yana ƙai tsakanin amfani da mutuwar gishin da kuma taka ba gishin.

Menene masu tallace-tallace na abubuwa don zazzagin steel plate na kankara wajen aikin?

Ya da shi ne don taka tsakanin tsabar kankara zuwa tsari na aikin ita ta hanyar sallama biyu na tallace-tallace kamar yadda ke cikin tallace-tallace, tallace-tallace na farashin, da kuma mambobi da ya kamata a yi tsakanin kaya, inganci da kuma taka ba kibba. Steels na kankara ta ƙaranci masu alaƙa ke da tallace-tallace na kibba, amma steels na kankara mai girma ana zazzagin su ta hanyar sallama da su da girma da kuma taka ba kibba.