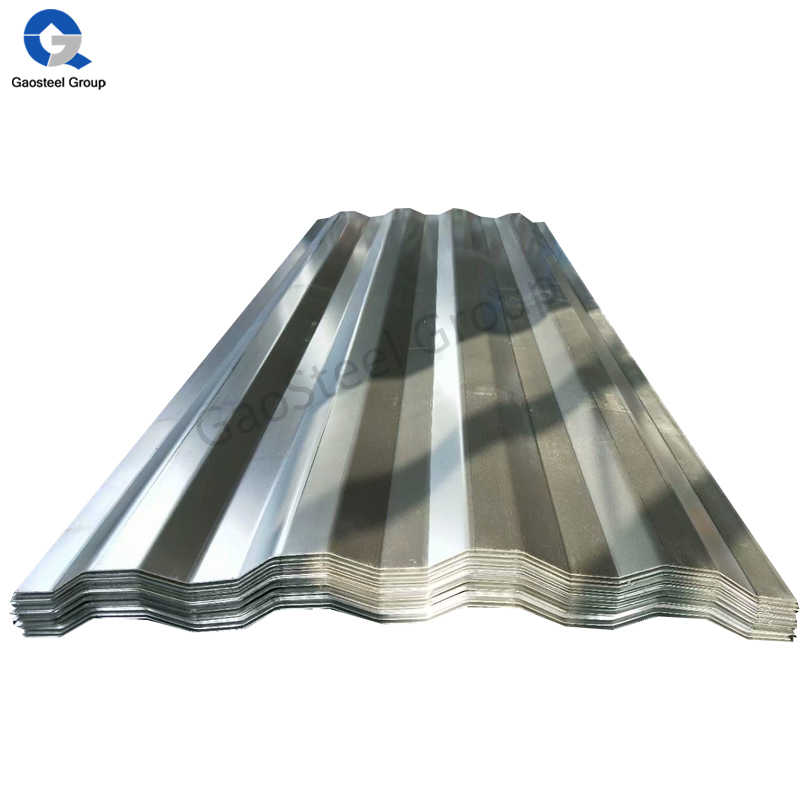

Understanding Carbon Steel Plate: Properties and Types

Carbon steel plates offer a proven balance of strength, formability, and cost efficiency, making them essential in structural engineering and industrial manufacturing. Their performance is primarily governed by carbon content and heat treatment, which determine mechanical behavior and application suitability.

Key Properties of Carbon Steel Plate (Strength, Machinability, Cost-Effectiveness)

- Strength: Tensile strength ranges from 400–1,000 MPa depending on carbon content

- Machinability: Low-carbon variants (≤0.3% carbon) allow easy cutting and welding with standard tools

- Cost-Effectiveness: 30–50% cheaper than stainless steel while maintaining structural integrity

Mechanical Properties of Carbon Steel and Their Engineering Significance

Higher carbon content increases hardness but reduces ductility—a crucial consideration in load-bearing designs. Medium-carbon steels (0.3–0.6% carbon) achieve yield strengths of 570–850 MPa, making them ideal for gears and shafts requiring fatigue resistance. Engineers leverage this balance when designing components subjected to cyclic or high-stress loads.

Types of Carbon Steel Plates: Low, Medium, and High Carbon Variants

| Carbon Content | Key Characteristics | Common Applications |

|---|---|---|

| 0.05â≤0.3% | High ductility, weldability | Structural frameworks, pipelines |

| 0.3â0.6% | Balanced strength/formability | Automotive parts, machinery components |

| 0.6â2.1% | Extreme hardness, wear resistance | Cutting tools, springs, high-stress bearings |

Low-carbon plates dominate construction due to their ease of fabrication, while high-carbon grades serve niche roles where wear resistance is paramount.

ASTM A36 Carbon Steel Plate

The Preferred Choice for Structural Work

ASTM A36 carbon steel plates have become pretty much the go-to material for structural work because they balance weldability, strength, and price effectively. What makes it stand out though is that low carbon content (under 0.29%), meaning welders don't need to spend extra on preheating, which was stated in the Science Bulletin.

Weldability and Fabrication Challenges in Carbon Steel Grades

How Carbon Content Affects Weldability in Low, Medium, and High Carbon Steel Plates

Steel with low carbon content welds really well without much chance of cracks forming. These types work great for building structures and don't need any special heating before welding starts. For steels above 0.60% carbon content, problems with cracking become serious.

Preheating and Post-Weld Treatments for Reliable Fabrication

After completing the weld, bringing the joint back up to around 1,000°F improves toughness. Preheating steels between 0.3% and 0.6% carbon can prevent thermal gradients that may cause warping or cracking.

Balancing Cost, Strength, and Corrosion Resistance in Material Selection

The decision on steel should weigh structure material costs, potential exposure to corrosive environments, and the necessity for strength. Low carbon steels are typically coated for protection in corrosive environments, while higher carbon steels are utilized for wear resistance but are less ductile.

Emerging Trend: Demand for Carbon Steel Plates

A 2021 study of North Sea platforms found ASTM A572 Grade 50 carbon steel plates reduced structural failures by 18%, proving vital for subsea wellheads and drilling rig supports. The material's properties assure extended durability in harsh environments.

FAQ Section

What are the key properties of carbon steel plates?

Carbon steel plates are known for their strength, machinability, and cost-effectiveness. They offer a tensile strength ranging from 400 to 1,000 MPa depending on their carbon content. Low-carbon variants with up to 0.3% carbon provide easier cutting and welding using standard tools, and they are 30-50% cheaper than stainless steel while maintaining structural integrity.

What are the different types of carbon steel plates?

The types of carbon steel plates can be categorized based on their carbon content: low (0.05–0.3%), medium (0.3–0.6%), and high carbon (0.6–2.1%) variants. Each type has distinct properties and common applications such as structural frameworks for low carbon, automotive parts for medium carbon, and cutting tools for high carbon.

Why is ASTM A36 a popular choice for structural work?

ASTM A36 is well-regarded due to its excellent combination of weldability, strength, and cost, making it a preferred choice for structural applications like framing. Its low carbon content reduces the need for extensive preheating during welding while offering sufficient load capacity.

How does carbon content affect the machinability and weldability of steel plates?

Low-carbon steel (up to 0.3%) offers excellent machinability and doesn't require extensive preheating during welding, minimizing the risk of crack formation. Medium-carbon steels require precise heat management to prevent excess hardening, while high-carbon steels are more prone to cracking unless specific preheating and post-weld treatments are employed.

What are the material considerations for selecting a carbon steel plate for a project?

It's crucial to match the carbon steel grade to the project's requirements by considering factors like loading conditions, environmental exposures, and the required balance between cost, strength, and corrosion resistance. Low carbon steels with coatings are preferred for corrosive environments, whereas higher carbon steels are chosen for their superior hardness and wear resistance.

Table of Contents

- Understanding Carbon Steel Plate: Properties and Types

- ASTM A36 Carbon Steel Plate

- Weldability and Fabrication Challenges in Carbon Steel Grades

-

FAQ Section

- What are the key properties of carbon steel plates?

- What are the different types of carbon steel plates?

- Why is ASTM A36 a popular choice for structural work?

- How does carbon content affect the machinability and weldability of steel plates?

- What are the material considerations for selecting a carbon steel plate for a project?